The UNICELL®-Difference

Corrosion Resistant Advanced Composite

Our advanced technology vinylester-based composite is specifically designed to provide superior chemical resistance and mechanical durability, withstanding the extreme environment of a refinery tank house.

Monolithic Construction

The UNICELL® is the originally monolithically cast electrolytic cell with integrated overflow/decant and inlet piping systems. Eliminating cold joints and seams from cell designs has reduced long-term maintenance costs.

Non-Conductive FRP Rebar Reinforcement

Fiberglass Reinforced Plastic Rebar provides structural protection against catastrophic failure to each UNICELL® without the possibility of creating short circuits.

Easy Installation

Pre-cast piping connections ensure an effortless field hook-up, save expensive labour and materials, eliminate unnecessary downtime, and thereby improve overall productivity.

Advanced Wall Construction

STEULER-CTI’s advanced composite technology allows UNICELL® wall designs that support electrodes and electrolyte with minimal deflection. Sleek wall design allows a tank house to add additional cells of electrodes to increase production capacity.

UNICELL® ADVANCED DESIGN OPTIONS

Patented Integrally Cast Piping Systems

STEULER-CTI offers a variety of proven integrally cast piping systems. Pre-cast piping that is protected by STEULER-CTI’s advanced technical composite decreases initial installation expenses, costly production downtime and long-term maintenance costs.

Customised Inlet Designs

STEULER-CTI has inlet options for a variety of electrolyte flow patterns and fast filling capabilities. These precisely planned features provide better electrolyte flow control.

Overflow and Decant Designs

All UNICELLs® contain a proven integrated cast overflow arrangement. Overflow designs are available that can allow decantation at a controlled level without disturbing slimes to aid in maintaining clarity of the electrolyte, reducing unnecessary slimes treatment.

Sloped UNICELL® Bottom Designs

The slope of the UNICELL® floor is dependent on the needs of each individual tankhouse. STEULER-CTI has numerous options that can increase tankhouse productivity and slimes recovery.

MORE THAN JUST CELLS

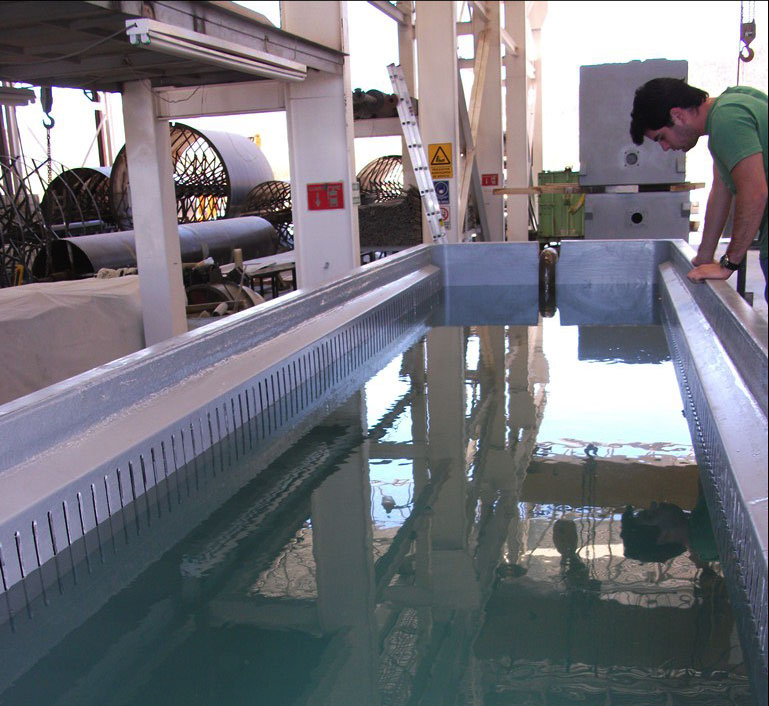

INSTALLATION

STEULER-CTI not only manufactures and supplies UNICELLs®. We can install them as well, whether on Greenfield sites, or replacing old cells in existing refineries. Our expertise covers the entire project requirement:

- Detailed project planning including development of work plans, safety plans, work schedules and the like, from power down to power up

- Demolition of existing cell assembly including removal of liners, pipework and all other connected equipment

- Rehabilitation of existing support structures

- Erection of UNICELLs® including placement and levelling

- Supply and connection of piping systems, pipe hangers etc

- Re-fitting walkways

- Testing and re-commissioning of cell arrangement